15TE 2 Jaw Tensioner Horizontal

This robust continuous track tensioner is a PLC controlled system consisting of two horizontally mounted track carriages with polyurethane 'V' shaped pads. A variety of pad profiles are available. The design is open on the top side, allowing access for easy loading of product on to the tracks.

| Drive type | Hydraulic |

| No. of tracks | 2 |

| Track orientation | Horizontal |

| Track length | 2.4m |

| Total maximum grip | 80Te |

| Maximum speed | 1100m/hr |

| Constant tension mode | Yes |

| HPU / EPU | Twin HPUs |

| Remote display | Yes |

15TE 2 Jaw Tensioner Vertical

This robust continuous track tensioner is a PLC controlled system consisting of two vertically mounted track carriages with polyurethane 'V' shaped pads. A variety of pad profiles are available. The design is open on one side, allowing access for easy loading of product on to the tracks.

| Drive type | Hydraulic |

| No. of tracks | 2 |

| Track orientation | Vertical |

| Track length | 3.6m |

| Total maximum grip | 80Te |

| Maximum speed | 1100m/hr |

| Constant tension mode | Yes |

| HPU / EPU | Twin HPUs |

| Remote display | Yes |

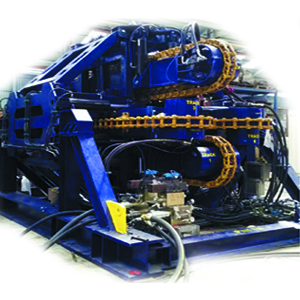

30Te 4 Jaw Tensioner

This robust continuous track tensioner is a PLC controlled system consisting of four mounted track carriages with polyurethane 'V' shaped pads. A variety of pad profiles are available. The design is open on one side, allowing access for easy loading of product on to the tracks. To allow the product to be removed from the tensioner in mid line, or where end terminations are too large to pass through the tensioner, the top track opens by hinging to one side. The unique method employed to do this maintains the opening track within the tensioner width thereby minimizing deck space requirements.

| Drive type | Hydraulic |

| No. of tracks | 4 |

| Track orientation | Horizontal + Vertical |

| Track length | 2.4m |

| Total maximum grip | 110Te |

| Maximum speed | 1100m/hr |

| Constant tension mode | Yes |

| HPU / EPU | Twin HPUs |

| Remote display | Yes |

60Te 4 Jaw Tensioner

This robust continuous track tensioner is a PLC controlled system consisting of four mounted track carriages with polyurethane 'V' shaped pads. A variety of pad profiles are available. The design is open on one side, allowing access for easy loading of product on to the tracks. To allow the product to be removed from the tensioner in mid line, or where end terminations are too large to pass through the tensioner, the top track opens by hinging to one side. The unique method employed to do this maintains the opening track within the tensioner width thereby minimizing deck space requirements.

| Drive type | Hydraulic |

| No. of tracks | 4 |

| Track orientation | Horizontal + Vertical |

| Track length | 3.5m |

| Total maximum grip | 205Te |

| Maximum speed | 1100m/hr |

| Constant tension mode | Yes |

| HPU / EPU | Twin HPUs |

| Remote display | Yes |

320Te Reel Hub

The 320Ton Hub Drive is a tower drive system for handling umbilical & flexible hoses. The Horizontal hydraulic jacks engage the drive hubs to the reel. The system is capable of handling multiple reels. The hub drive is powered by diesel engine power pack

| Drive type | Hydraulic |

| Lifting | Hydraulic |

| Skidding | Hydraulic |

| Track System | Any Length |

| Weight | 320Te |

| Modular | Yes |

| Torque | 607kNm |

| HPU / EPU | Both |

| Remote display | Yes |

320Te Reel Drive Base

| Drive type | Hydraulic |

| Weight | 320Te |

| Modular | Yes |

| Torque | 607kNm |

| HPU / EPU | Both |

| Remote display | Yes |

100Te Modular Drive System

150 ton Modular Drive System & power pack unit is a Modular Drive mechanism. The power pack is equipped with a 215 hp engine driven to cater for the job requirement. The system is a positive pin drive that engages and spins the reel. Centre pedestal is movable.

| Engine Horsepower | 215HP |

| System Flow | 60 GPM |

| System Pressure | 3600 PSI |

| Diesel Tank Capacity | 200 Gallon |

| Oil Tank Capacity | 200 Gallon |

| Line Pull | 5ton @ PCD 400 |

| Speed | 26.82M/MIN @ PCD 4000 |

| Main Shaft | Dia 240mm |

| Reel Weight w/Pdt | 150Ton Max |

| Reel Diameter | Dia 7.4m Max. Can accommodate various widths |

150Te Modular Drive System

150 ton Modular Drive System & power pack unit is a Modular Drive mechanism. The power pack is equipped with a 215 hp engine driven to cater for the job requirement. The system is a positive pin drive that engages and spins the reel. Centre pedestal is movable.

| Drive type | Hydraulic |

| No. of tracks | 4 |

| Track orientation | Horizontal + Vertical |

| Track length | 3.5m |

| Total maximum grip | 205Te |

| Maximum speed | 1100m/hr |

| Constant tension mode | Yes |

| HPU / EPU | Twin HPUs |

| Remote display | Yes |

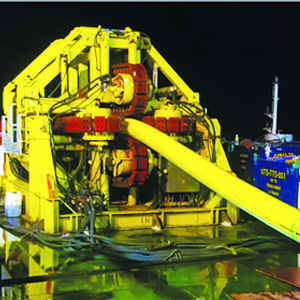

50TE HORIZONTAL LAY SPREAD (HLS)

The lay system designed for Underwater Technology Services is classified as a horizontal lay system (HLS), although it is appreciated that the tensioner sits on an incline rather than horizontal to reduce the overall dimensions of the system. The principal components of the lay system are as follows:

1. HLS Tower – This is the primary structure of the lay spread and is used to support both the tensioner, and the lay chute.

2. Tensioner – The tensioner can be either a 2-track, or 4-track caterpillar type system, which through hydraulic squeeze on the product, and friction between the V-shaped track pads and product coating, can support the catenary load of the product. The rating of the product is generally inclusive of dynamic factors.

3. Lay Chute – The lay chute is the mechanism for taking the product from the horizontal plane to the vertical (or the required catenary angle) while ensuring the MBR of the product is not jeopardised. Water jets or deluge systems are generally installed on the chute to minimise friction between the chute and the product.

4. Work Platform – The work platform is required for the installation of buoyancy modules, anodes, the make-up of midline connectors, and any other pieces of equipment which cannot be passed over the lay chute. The work platform also houses a bell mouth, which is used to control the exit radius of the product from the vessel and it is hydraulically actuated.

50TE COILED TUBING SPOOLER

Unique, rigid & robust steel structure for both onshore & offshore applications. Compact telescopic skid and foldable design for convenient transportation of the CIR frame. Provides the combined functions of coiled tubing power reel and spooler frame.

| Max output Turning Speed | 5 RPM (9RPM Max) |

| System Pressure | 3000 PSI |

| System Flowrate | 30 GPM |

| Oil Tank Capacity | 200 Gallon |

| Line Pull | 5ton @ PCD 4000 |

| Speed | 26.82M/MIN @ PCD 4000 |

| Reel Weight w/Pdt | 50 Ton Max |

| Reel Diameter | Dia 6.0M |

OVERBOARD CHUTE 3.8M RADIUS

OVERBOARD CHUTE 4M RADIUS

DECK DEFLECTOR

RIGGING CONTAINER

List of items in the container

1.Bulldog Grips Size 6mm to 25mm

2.Cargo Straps 5m Long 2-8 TON

3.Chain Blocks 1 TON – 5TON

4.Lever Hoists 1- 5 TON

5.Masterlink Rings 6.5 – 22 TON

6.Polypropylene Rope 100M 6, 8, 10, 12mm Diameter

7.Elastic Bungee Cables 6 – 12mm Diameter

8.Shackles Bow Type with Bolt & Nut 2 – 15 TON

9.Sling – Flat Webbing 3m 2 – 15 Ton

10.Sling – Wire Rope 3m 6mm 10mm 12mm 1 coil each

11.Snatch Blocks 5 – 10 Ton

12.Turnbuckles Various

TOOLS CONTAINER

List of items in the container

1.Crimping Tool

2. Electrical Plugs & Sockets

3. Impact Gun & Wrench

4. Jigsaw with Wood & Metal Blades

5. Megger and Multi Meter

6. Air Hose Chicago Fittings 1 – 2”

7. Greasing Kit

8. Enerpac Hydraulic Jacks with Handpumps

9. Bench Vice

10. Wrench Monkey, Pipe type 8-36”

11. Torque Wrench 150 -1500Nm

12. Bearing Extractor Kits

13. Portable Welding Machine 15A

14. Welding Consumables